The process behind Aluminum Casting and why it matters for manufacturers

The Function of Aluminum Factory in Numerous Industries: Applications and Upkeep Insights

Aluminum factories are vital in numerous sectors, providing lightweight and long lasting elements that significantly influence product performance. Their applications cover from auto engine obstructs to aerospace architectural parts. However, the effectiveness of these factories depends greatly on rigorous upkeep practices and the integration of sophisticated modern technologies. Comprehending these characteristics exposes a complicated interaction of technology and practice, prompting further exploration right into the future fads forming this essential sector.

Overview of Light Weight Aluminum Foundries and Their Procedures

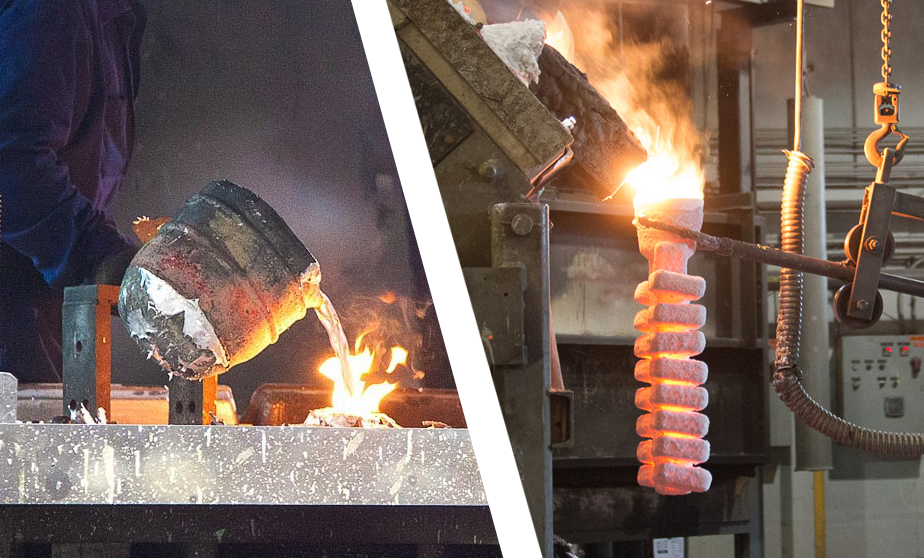

Light weight aluminum shops play a vital function in the production market, specializing in the spreading of aluminum components. These facilities employ numerous procedures to transform raw light weight aluminum right into completed products, starting with melting scrap or ingots in high-temperature furnaces. As soon as thawed, the aluminum is put right into molds, which can be made from steel, sand, or ceramic, relying on the preferred finish and application.

After cooling down, the cast components go through added procedures such as cutting, machining, and surface area finishing to meet visual demands and certain tolerances. aluminum metal casting. Quality assurance is vital; foundries apply extensive testing techniques to determine that the end products satisfy sector requirements

The adaptability of aluminum as a product allows for a large range of parts and designs, making factories essential for numerous industries. Their knowledge in taking care of aluminum assurances that manufacturers get high-quality components vital for subsequent setting up and usage.

Applications in the Automotive Industry

While the automobile sector increasingly seeks light-weight products to enhance fuel performance and efficiency, aluminum foundries have come to be vital distributors of various elements. These factories generate critical parts such as engine blocks, transmission housings, and wheels, which contribute to minimized automobile weight and improved handling. The convenience of aluminum permits for complicated geometries, making it suitable for detailed layouts in both architectural and visual applications.

Additionally, light weight aluminum spreadings are preferred for their excellent corrosion resistance and recyclability, lining up with the sector's sustainability objectives. Making use of aluminum in electric cars is likewise growing, as it sustains effective battery styles and thermal management systems. With constant improvements in casting technologies, aluminum shops are outfitted to fulfill the ever-evolving needs of the vehicle sector, ensuring that manufacturers can deliver high-performance lorries that satisfy consumer expectations for effectiveness and sustainability.

Aerospace Sector Usage of Aluminum Castings

The aerospace industry significantly counts on light weight aluminum castings for a selection of critical applications, driven by the demand for light-weight and high-strength products. Aluminum spreadings play an essential role in manufacturing elements such as engine installs, brackets, and structural airframe components. The integral homes of aluminum, consisting of excellent corrosion resistance and exhaustion stamina, make it a perfect selection for aerospace applications, where performance and safety and security are vital.

Aluminum castings facilitate intricate styles and geometries that can enhance wind resistant effectiveness. The capacity to create complex shapes while decreasing weight is necessary in optimizing fuel performance and overall airplane efficiency. Makers utilize advanced spreading techniques such as sand and die casting to attain the required precision and high quality. In addition, the recyclability of aluminum lines up with the market's sustainability objectives, further solidifying its value in aerospace. As technology advancements, the use of light weight aluminum castings is expected to expand, satisfying the advancing demands of the aerospace sector.

Building Market and Light Weight Aluminum Foundries

In the building and construction sector, aluminum foundries play a considerable function by supplying products that boost architectural honesty and reduce overall weight in building projects. Aluminum spreadings are preferred for their strength-to-weight ratio, making them perfect for different applications, consisting of windows, doors, and architectural components. The light-weight nature of light weight aluminum not just facilitates simpler handling and transportation but also contributes to power performance in structures.

Aluminum's resistance to corrosion warranties longevity and minimizes upkeep expenses, which is necessary for framework jobs. Factories create personalized parts customized to particular architectural designs, enabling ingenious building services. In addition, innovations in aluminum alloy technology have actually expanded the variety of applications, allowing using light weight aluminum in high-stress atmospheres. By sustaining sustainable building methods, aluminum factories contribute to the total efficiency and sturdiness of building and construction jobs, making them important companions in the market.

Customer Product and House Applications

Aluminum shops significantly add to the durable goods industry by generating a variety of house items that incorporate performance with aesthetic charm. From kitchenware to home decor, light weight aluminum works as a flexible product, guaranteeing items are both light-weight and resilient. Popular products consist of cookware, such as pots and pans, which profit from aluminum's outstanding thermal conductivity, making food preparation more efficient.

Furthermore, light weight aluminum's corrosion resistance enhances the durability of house items, decreasing the requirement for constant replacements. Decorative aspects, such as light weight aluminum image frames and lighting fixtures, showcase the steel's capacity to be formed right into detailed layouts while keeping a modern visual.

The green nature of light weight aluminum, being recyclable, straightens with customer choices for sustainable products. Aluminum Casting. Consequently, aluminum shops play an important duty in meeting the varied demands of families, supplying necessary products that enhance everyday living while addressing ecological worries

Upkeep Finest Practices for Spreading Tools

Efficient upkeep of spreading equipment is crucial for peak efficiency and longevity. Normal equipment inspections, appropriate lubrication and cleaning, and thorough driver training programs are crucial parts of an effective maintenance technique. Carrying out these best techniques can considerably reduce downtime and improve overall manufacturing efficiency in light weight aluminum shops.

Routine Tools Evaluations

Normal equipment examinations play a crucial function in keeping the efficiency and security of casting operations. These inspections involve a methodical analysis of devices to determine wear, damages, or potential failings prior to they rise into expensive failures. By adhering to a routine assessment timetable, foundries can establish that all casting equipment operates at peak performance, thus decreasing downtime and optimizing performance. Evaluations must incorporate essential components such as molds, heating systems, and cooling systems, enabling for the prompt substitute or repair of components. Additionally, documentation of evaluation findings is necessary for tracking tools background and educating future maintenance choices. Inevitably, normal inspections contribute considerably to the longevity of tools and the total success of light weight aluminum shop procedures.

Lubrication and Cleaning

Proper lubrication and cleansing are essential parts of upkeep methods for casting devices in factories. Normal lubrication minimizes damage on equipment, guaranteeing that components operate efficiently and effectively. It is crucial to make use of the ideal lubricating substances defined by makers, as different tools might need varied materials to work at peak performance.

Cleansing devices removes impurities and particles that can hinder procedures and cause problems in spreadings. Arranged cleaning regimens should be developed to avoid buildup and lengthen equipment life. In enhancement, operators should comply with safety methods while managing cleaning up representatives to preserve a secure workplace. By prioritizing lubrication and cleansing, foundries can improve the reliability and efficiency of their casting devices, ultimately contributing to better production top quality.

Operator Training Programs

While preserving spreading tools is important for excellent performance, comprehensive operator training programs play a considerable role in making sure that employees are fully equipped to take care of maintenance tasks properly. These programs should concentrate on the details operational elements of light weight aluminum shop equipment, including security methods, troubleshooting techniques, and routine maintenance treatments. By giving hands-on training and comprehensive academic expertise, drivers can develop a deeper understanding of devices capability and helpful resources potential issues. Regular evaluations and refresher course training courses can boost ability retention and adjust to technical advancements. Eventually, purchasing driver training not just enhances total manufacturing performance but also minimizes downtime, resulting in enhanced security and prolonged equipment lifespan in the aluminum shop sector.

Future Fads in Light Weight Aluminum Factory Applications

The future of aluminum foundry applications is poised for transformation via sophisticated casting modern technologies that improve effectiveness and precision. Additionally, sustainable production practices are obtaining grip, showing a growing commitment to ecological duty within the market. Furthermore, the integration of Industry 4.0 concepts is set to transform operations, making it possible for smarter producing processes and real-time information application.

Advanced Casting Technologies

Technologies in sophisticated spreading technologies are poised to revolutionize aluminum foundry applications, driving efficiency and accuracy in the manufacturing procedure. Techniques such as 3D printing and progressed die-casting are acquiring grip, allowing the manufacturing of complicated geometries that traditional techniques battle to accomplish. In addition, the combination of automation and AI in the spreading process improves quality assurance and minimizes material waste. These innovations facilitate fast prototyping, allowing for quicker design models and decreased time-to-market. Innovations in mold materials and cooling down systems enhance thermal monitoring, guaranteeing constant component top quality. As industries demand lighter, more powerful parts, these innovative casting innovations are ending up being essential in markets such as auto, aerospace, and electronics, positioning aluminum foundries at the leading edge of advancement.

Sustainable Production Practices

Advanced casting innovations not just boost efficiency and accuracy yet additionally pave the way for lasting production practices in aluminum factories. These methods focus on lowering waste, energy consumption, and exhausts throughout the manufacturing process. The fostering of recycled light weight aluminum is significantly prioritized, decreasing the demand for key steel extraction and reducing the environmental footprint. Additionally, advancements in mold and mildew products and cooling techniques contribute to power financial savings and faster production cycles. Carrying out closed-loop water systems further sustains sustainability by lowering water usage and avoiding pollution. As shops accept these environment-friendly techniques, they not only abide by laws however also fulfill the expanding demand for lasting items across different markets, strengthening their dedication to environmental stewardship.

Sector 4.0 Combination

As aluminum shops increasingly welcome Industry 4.0 assimilation, they are leveraging clever innovations to maximize manufacturing processes and enhance functional effectiveness. The fostering of IoT devices allows real-time surveillance of equipment and manufacturing metrics, facilitating predictive upkeep and reducing downtime. Advanced data analytics and expert system enable for enhanced decision-making, leading to much more specific spreading and reduced waste. Robotics and automation enhance recurring jobs, enhancing labor efficiency. Furthermore, electronic doubles enable virtual simulations of factory procedures, aiding in procedure optimization and layout improvements. look at here This integration not only increases efficiency however additionally sustains sustainability campaigns by minimizing energy consumption and resource use, positioning aluminum foundries to meet the developing demands of different sectors in a competitive market landscape.

Regularly Asked Inquiries

What Are the Ecological Effects of Aluminum Foundries?

Light weight aluminum shops add to ecological influences via greenhouse gas exhausts, power intake, and waste generation. In addition, they might present dangers of air and water contamination, requiring efficient management practices to mitigate these adverse effects.

How Do Light Weight Aluminum Foundries Ensure Item High Quality?

Aluminum foundries assure item high quality through rigorous top quality control actions, consisting of product examinations, exact temperature monitoring, and adherence to sector requirements. Continuous training of personnel and execution of sophisticated innovations further boost the consistency of their output.

What Safety and security Procedures Are in Area in Aluminum Foundries?

Light weight aluminum factories implement security measures consisting of protective gear for workers, emergency situation reaction plans, air flow systems to reduce fumes, regular security training, and adherence to industry guidelines to guarantee a protected functioning environment and protect against mishaps.

Just How Do Factories Take Care Of Waste and Recycling?

Factories manage waste and recycling by applying systems for gathering scrap light weight aluminum, reusing products, and sticking to environmental laws. They prioritize lowering waste through reliable procedures and purchasing modern technology for effective recycling initiatives.

What Certifications Are Appropriate for Light Weight Aluminum Foundries?

Relevant accreditations for light weight aluminum foundries include ISO 9001 for top quality management, ISO 14001 for environmental monitoring, and AS9100 for aerospace criteria. These certifications ensure conformity, enhance high quality control, and advertise lasting practices within the factory procedures.

Aluminum factories play an essential duty in the manufacturing market, specializing in the spreading of light weight aluminum components. While the automobile market significantly looks for light-weight products to enhance fuel efficiency and performance, aluminum foundries have ended up being necessary distributors of numerous components. Furthermore, advancements in aluminum alloy innovation have actually expanded the array of applications, allowing the use of aluminum in high-stress atmospheres. The future of light weight aluminum shop applications is poised for check here transformation through advanced spreading modern technologies that boost performance and accuracy. As light weight aluminum factories progressively embrace Industry 4.0 assimilation, they are leveraging wise innovations to optimize production procedures and improve operational efficiency.